MINTERROR NEWS.COMTM

Bringing the latest mint error news to the collector. Also featuring Die Trials, Patterns, Test Pieces, Numismatic Rarities, Currency Errors and Discoveries from the U.S. Mint.

|

|

|

Features

Curved Clip Coins

We have witnessed a resurgence of non-genuine curved clip coins entering the market place. While most “faked clips” are usually easy to spot because of the crudeness of their fabrication, this is not always the case.

Learn the Diagnostics of Authentic Mint Made Curved Clips

We have witnessed a resurgence of non-genuine curved clip coins entering the market place. While most “faked clips” are usually easy to spot because of the crudeness of their fabrication, this is not always the case. A substantial amount of elaborate fakes of coins dated within the past two years have surfaced. Who is making them is still unknown, but the lure of easy money is probably the driving force. So how can a mint made clip be distinguished from a clip fabricated outside the mint after striking? There are three foolproof characteristics that we’ll examine which will answer this question: cut and tear marks, weak rims, and metal flow.

It is important to note that clipped planchets are actually incomplete planchets and occur pre-striking.

Planchets are the round material upon which the dies impart an image. They begin as long coils of metal that are 13 inches wide. These coils are fed into the blanking machine which punches out metal disks from this strip. The resulting blanks (Type 1) are only slightly larger in diameter than the finished planchets. The blanks are then annealed and washed (Type 2). The final step comes when these blanks have a raised rim applied to them (a process called upsetting) from which they emerge as planchets.

With this in mind, the first thing to look at is the shape and edge of the clip. The clip must have an arc similar in fashion to that of the coin. It may not be the perfect shape, because it gets distorted slightly when struck, but it should be close. Therefore, if another coin of the same denomination is placed alongside this coin, it should almost “fit” into the area that is missing.

Next, by looking at the edge of the clip area, there will be tell tale signs that it was “punched out” of the strip. Photo #4 illustrates what is referred to as “cut and tear” marks, which are always present on mint made clips. This phenomenon occurs during the first stage of making the planchets when it is “punched out” of the metal strip. The punch does not penetrate the strip completely. Instead, it cuts only partially through, the planchet then being “pushed” the rest of the way through a shearing action.

The next area to look at is the rim of the coin (obverse and reverse) that is directly opposite the clip. The rim in this area will be wider and weaker than the rest of the coin which can be seen in Photo #5. This occurs because the planchet lacks upsetting in this area. The rim could not be “raised,” since there was no opposing side to force it up.

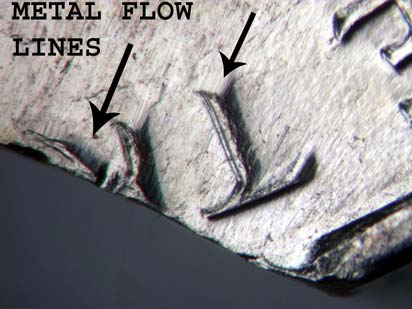

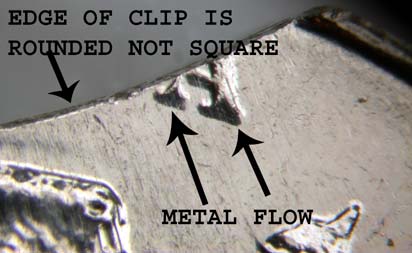

Lastly, we will look at the design elements of the coin surrounding the clip. Photos #6 and #7 are of the obverse of the coin by the clip area. When a coin is struck, metal will flow into the dies. It will flow into the areas of least resistance first. For this reason, the details (wording and design elements) of the coin will be distorted in the areas closest to the clip. There will be “flow lines” where the metal is moving towards the clip. The same will be true of the reverse of the coin. Additionally, the edge of the clip should be rounded on each side of the coin since the metal is flowing and curving into that area of the clip. This can be seen in Photo #8.

Clips are measured in terms of percent of missing metal from the planchets. In this case, these planchets are missing 15% of their metal (weighs 4.5 grams) or have a 15% curved clip. Since curved clips form an arch, gauges are usually employed to measure clips which are measured in increments of 5%. Curved clip is used (with no mention of %) when less than 5%.

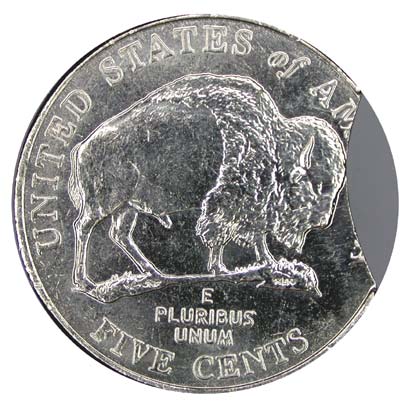

Photos 1 & 2: Clipped 2005-D Bison 5¢.

Photo 3: A strip from which planchet blanks are cut.

Photo 4: A close up of the above clipped coins edge, showing “cut and tear.”

Photo 5: The broad and flat rims area opposing the clip, where

the planchet was not upset. Obverse is at left, and reverse at right.

Photo 6: A close up of obverse clipped edge, showing distinctive directional metal.

Photo 7: Another close-up of obverse clipped edge, also showing metal flow.

Photo 8: The curved clip as seen on reverse.

|

|

|

|

|

|

Copyright Ⓒ 2014 minterrornews.com. All rights reserved. Legal Notice

|

|

|

|